3D Printing Materials Market Growth Driven by Advanced Uses in Aerospace, Automotive & Healthcare | DataMIntelligence

The 3D printing materials market is rapidly growing, fueled by aerospace, healthcare, and sustainability needs, reshaping the future of digital manufacturing.

The future of 3D printing hinges not just on machines but on the advanced materials that empower precision, strength, and sustainable manufacturing at scale.”

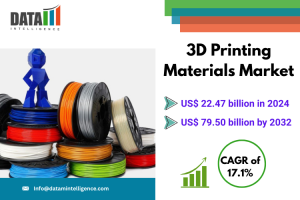

NEW YORK, NY, UNITED STATES, July 17, 2025 /EINPresswire.com/ -- The 3D Printing Materials Market is experiencing a transformative phase, driven by rapid advancements in additive manufacturing and the growing demand for lightweight, customized, and sustainable components across industries. Valued at USD 22.47 billion in 2024, the market is forecasted to reach USD 79.50 billion by 2032, growing at a robust CAGR of 17.11% during the forecast period. This surge is attributed to the rising adoption of 3D printing in automotive, aerospace, healthcare, and consumer electronics sectors, which are embracing the technology for its speed, precision, and ability to reduce material waste.— DataM Intelligence

Download Latest Sample Report Pdf :

https://datamintelligence.com/download-sample/3d-printing-materials-market

3D Printing materials market drivers are :

Expanding Use in Aerospace and Automotive: Demand for lightweight and durable components is driving the uptake of high-performance 3D printing materials.

Customization in Healthcare: Growing need for patient-specific implants, prosthetics, and medical devices supports material innovations in biocompatible polymers and metals.

Sustainability Focus: Increasing use of bio-based and recyclable materials is aligning with global sustainability goals.

Rapid Prototyping Advantages: Shorter product development cycles and cost savings in prototyping fuel adoption across industries.

Government and Defense Investments: Rising defense budgets and R&D funding in developed countries stimulate demand for advanced materials.

Material Innovation: Ongoing development of composite filaments, high-strength resins, and metal powders enhances application scope.

Lowering Material Costs: Economies of scale and local sourcing are helping bring down the cost barriers for end-users.

Key Players in the 3D Printing materials market are :

The competitive landscape of the 3D printing materials market is marked by strong innovation and strategic partnerships among top players:

3D Systems Corporation - A global leader in polymer materials and industrial-grade 3D printers.

Arkema SA - Known for its Rilsan and Pebax materials used in high-performance 3D printing.

Stratasys Ltd - Offers FDM and PolyJet printing materials for functional prototyping and production.

The ExOne Company - Specializes in binder jetting technology and industrial metal powders.

General Electric - Through GE Additive, focuses on metal additive manufacturing, especially for aerospace.

EOS GmbH Electro Optical Systems - A pioneer in metal and polymer laser sintering materials.

Materialise NV - Offers software and material solutions, with a strong focus on medical applications.

Sandvik AB - Produces high-quality metal powders for additive manufacturing in industrial applications.

Evonik Industries - A major supplier of nylon-based materials for additive manufacturing.

BASF SE - A key innovator in developing high-performance materials including photopolymers and thermoplastics.

Market Segmentation

By Material Type:

Polymers (Thermoplastics, Photopolymers)

Metals (Titanium, Stainless Steel, Aluminum)

Ceramics (Silica, Zirconia, Alumina)

Composites

Others (Bio-based and Sustainable Materials)

By Form:

Filament

Powder

Liquid/Resin

By Application:

Prototyping

Manufacturing

Tooling

R&D

By End-User:

Automotive

Aerospace & Defense

Healthcare

Consumer Goods

Construction

Education & Research

By Region:

North America

Europe

Asia-Pacific

South America

Middle East & Africa

Latest News in the USA (2025) :

In early 2025, Stratasys Ltd. partnered with Lockheed Martin to supply high-performance aerospace-grade thermoplastics for next-gen fighter jet components. Additionally, GE Additive announced the successful test of a fully 3D-printed aerospace engine bracket using titanium powders at its Ohio-based innovation center. The U.S. government also launched a new $120 million additive manufacturing initiative under the AM Forward program to support domestic innovation and materials development.

Latest News in Japan (2025) :

Mitsubishi Electric Corporation unveiled its collaboration with EOS GmbH to co-develop advanced laser sintering materials optimized for Japan’s industrial robotics sector. In another development, Japan's Ministry of Economy, Trade and Industry (METI) invested in a national 3D printing research hub, aiming to reduce reliance on imported metal powders by fostering local production. These moves underline Japan’s strategic shift toward becoming self-reliant in high-performance 3D printing materials.

3D Printing market recent Key Developments till Mid-2025 :-

BASF SE introduced an eco-friendly bio-based resin series for SLA printing, improving biodegradability without compromising strength.

Evonik Industries launched a new PA12-based powder with enhanced flowability and recyclability, ideal for industrial SLS printers.

3D Systems Corporation introduced VisiJet M2S-HT90, a high-temperature material designed for advanced prototyping in the aerospace and automotive industries.

Materialise NV expanded into Southeast Asia via a strategic joint venture focused on healthcare-specific materials research and development.

Sandvik AB significantly increased its titanium powder production capacity in Sweden to support the rising demand from the medical and aerospace sectors.

Conclusion :

The 3D printing materials market is on the cusp of a revolutionary leap forward, fueled by material science innovation, digital manufacturing integration, and growing demand for customized production. As industries embrace sustainable practices and faster product development cycles, the role of advanced 3D printing materials becomes even more critical. With robust growth projections and a wave of strategic advancements, the market presents vast opportunities for manufacturers, innovators, and investors alike. Continued R&D, localized material supply chains, and public-private collaborations are poised to shape the next frontier in additive manufacturing.

Purchase Your Subscription to Power Your Strategy with Precision: https://www.datamintelligence.com/reports-subscription

Browse more reports :

3D Printing Gases Market

3D Printing Plastics Market

Sai Kumar

DataM Intelligence 4market Research LLP

+1 877-441-4866

email us here

Visit us on social media:

LinkedIn

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.